My introduction to letterpress printing came in August 2007 when I

started working at Paper Source. We sell letterpressed invitations as

well as boxed sets of letterpressed cards. At first I was like

"ho-hum." And eventually I was like, "That is fantastic." Back in the

day, letterpress printing was the most common form of printing.

Newspapers were letterpressed. Books were letterpressed. Everything was

letterpressed. Now, it is usually just found on higher-end greeting cards and

wedding invitations (and prints and stationery and baby announcements

and business cards). It is considered more of an "art" and something

special as opposed to an everyday printing process.

took a beginner letterpress workshop in the spring of 2008 at a local

art studio called Pyramid Atlantic. The class was three hours on

three consecutive Saturdays and cost about $215. During the workshop, we learned

about the the process, had a chance to typeset, carved an image from a block and of course, used the presses. We learned on a

Vandercook printing press – which was originally designed to be used as

a proofing press before large runs of newspapers, etc. made it to the

larger printing machines.

the only press that I have experience printing on. It is characterized

by a large "bed" which is where the text, plate or image is set into

place. Presses come in all sort of sizes, shapes and weights. The type

of press that I would love to own someday is called a Chandler and

Price (Pilot?) which looks like the photo directly above. The smaller ones usually weigh about 250

pounds compared to the Vandercook which weighs well over 1000 pounds.

There is a video tutorial here if you would like to see how a smaller press works as well.

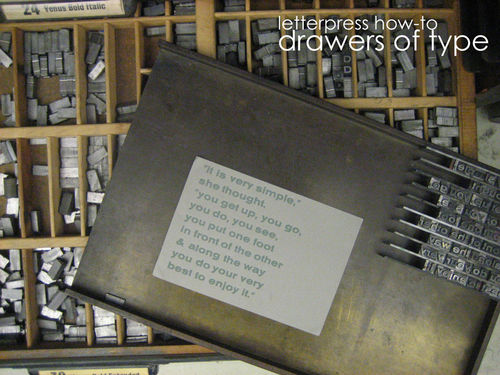

far, the only type of work I have done is with individual type. Pyramid

Atlantic has drawers and drawers of lead text. Each one looks very much

like this.

The drawers are divided into what is called California Job

Case style and the letters are housed in separate boxes. (The site

where the job case image is from called

it the QWERTY of the post-Gutenberg era.) Believe it or not, I am

getting good at remembering where each letter is stored.

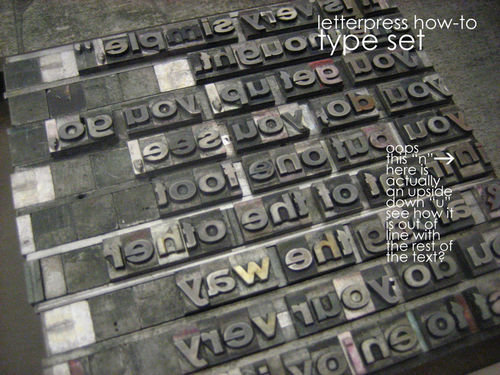

When you are

typesetting a block of text, the letters are placed in the reverse of

how they will be read on the page. Metal pieces called "slugs" divide

the lines of text. Hopefully seeing it like this explains why it is

not worth it to run a single print of anything. Too much work goes into

setting up the text. You can see above how I accidentally placed a letter "u" as an "n". "b" and "d" are also easy to mix-up. And the expression, "mind your 'p's' and 'q's'"? That comes from the letterpress days.

out of handset lead type and I make stationery out of wood block

letters that I purchased on etsy. The wood letters are much larger that

the lead text but are the exact same height. Everything that sits on

the press must be "type high" so it stands above the print bed and is just

high enough to make an indent and leave a mark when the paper is rolled

on top.

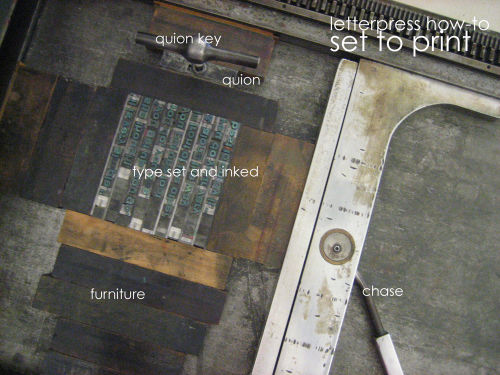

The text block is carefully transferred from the tray to the bed of the

press and then packed tightly with wood pieces called furniture. A chase

pushes up from the bottom and an expandable metal piece called a quoin is turned with a quoin key to put

pressure on the block from the side. Little pieces of copper and brass

get wedged into the text to eliminate remaining loose space. Everything

must be secure and "locked-in" to guarantee a clean image when the paper is rolled on

top.

plates. Most wedding invitations and graphics are designed in a program

like Illustrator and then emailed to a place like Owasso Graphics to

be turned into plates. I have yet to try this but I am sure I will

soon. While it seems much easier, I have not yet needed to work with

plates. The important thing to remember when ordering plates is that

you actually need the reverse of the image to be created and that the

plate should be secured on a wood block that is type high.

Vandercook that I use is electric and the ink rollers move on their own

with the flip of a switch. Currently, I use oil based printing ink

because it is easy to find locally. I would love to switch to something

rubber based or more eco-friendly. (Any brand recommendations?) I mix

the link and then spread it on to the top roller with what looks like a

putty knife. The rollers spin against each other and distribute the ink

evenly throughout the 4 other rollers (two of which will be used to ink the text).

printing process is relatively quick and methodical. A large crank is

manually turned in "trip mode" to first apply ink the text. The crank

is turned a second time, this time in "print mode" with paper

attached to the cylinder. A quick roll brings the paper over the inked text and leaves

an impression in the paper. The paper is removed and the whole inking

and printing process starts again.

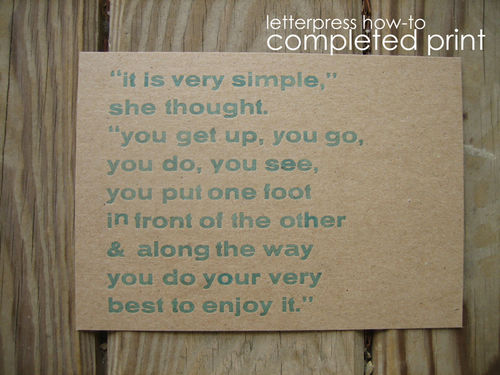

is printed in a separate run – you cannot print two colors at the same

time. For this reason, two color prints or invitations are usually

close to double the price of their single color counterparts. The above print is available here in teal and here in black.

is an old printing process that seems to be experiencing a

great revival. Currently, presses for sale are antiques and usually in

need of some love. I hope that some eccentric company starts making new

presses and materials again. How cool would that be? For now, it is a

little bit of a wild goose chase to track one down and then collect all

the parts to get it up and running.

are looking to try printing, I highly recommend taking a

workshop. If you are willing to travel, try taking a letterpress class

at Penland in North Carolina. To find something local, try a google search. Or look at briarpress.org which

is an online letterpress mecca. I know I am pretty lucky to be near a

rental studio. Now I just hope I am lucky enough to stumble on a press

for sale for under $2000.

through this behemoth of a post. Please leave your questions in the

comment area and I will be sure to do a Q+A follow-up.

Leave a reply to brook Cancel reply